Technology

Under Control Robotics Humanoid robot design system

Category

Expertise

To help people take on tough jobs more safely, Under Control Robotics teamed up with Teague to design a robot built for dynamic, high-impact work.

Challenge

Construction sites, warehouses, and disaster zones weren’t built for robots—they were built for people. That’s why the next generation of robotics is taking on a familiar form. With the ability to walk, climb, carry, and operate tools, humanoid robots are uniquely suited to work in spaces designed around human scale and movement.

But capability isn’t enough. For a robot to succeed in dynamic, high-stakes environments, it also has to communicate intent, signal trust, and integrate with the people around it from day one. That’s where Under Control Robotics (UCR) came in. Founded by engineers from NASA, Apple, and SpaceX, they had built a powerful humanoid platform with the intent of creating intelligent tools that enhance human capabilities and productivity, rather than simply mimicking the human form or behavior. They came to Teague to define its external form and visual language—to make it clear what the robot is, what it’s for, and how to work with it.

Approach

Teague’s work with UCR combined industrial design excellence with deep systems thinking. We helped shape not only how the robot looks, but the human machine interaction (HMI) and how it purposefully communicates its intent. We started by aligning the robot’s identity to its role: Should it look human at all?

Together, we determined that minimizing anthropomorphic features would increase acceptance on job sites by reinforcing the robot’s role as a smart and flexible tool, not a co-worker. This informed a broader design philosophy grounded in human-machine teaming, trust, and clarity of function.

We worked closely with UCR engineers to ensure that every external element supported the performance of actuators, joints, and vision systems. Our team made key recommendations that directly shaped the robot’s technical layout, including:

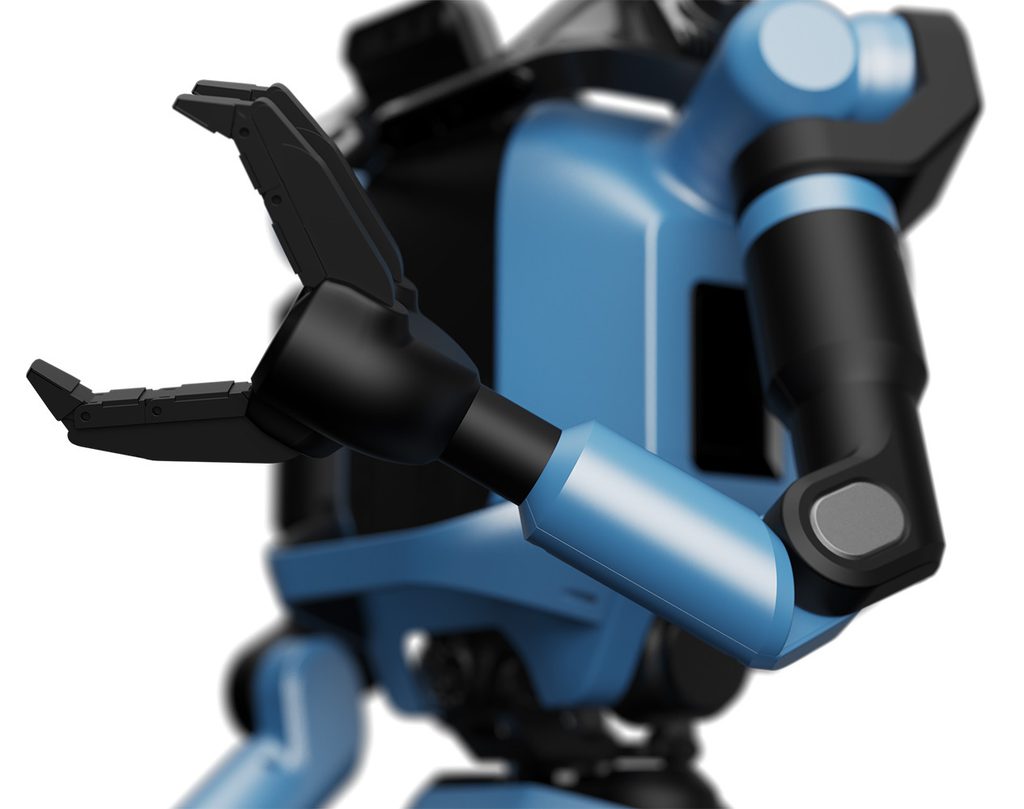

Inspired by professional rescue equipment, we established an aesthetic rooted in authenticity and intent. Instead of relying on superficial styling cues, we used material, form, and color to guide interaction: textured areas for grip, high-visibility handles for control, and exposed fasteners for honest assembly.

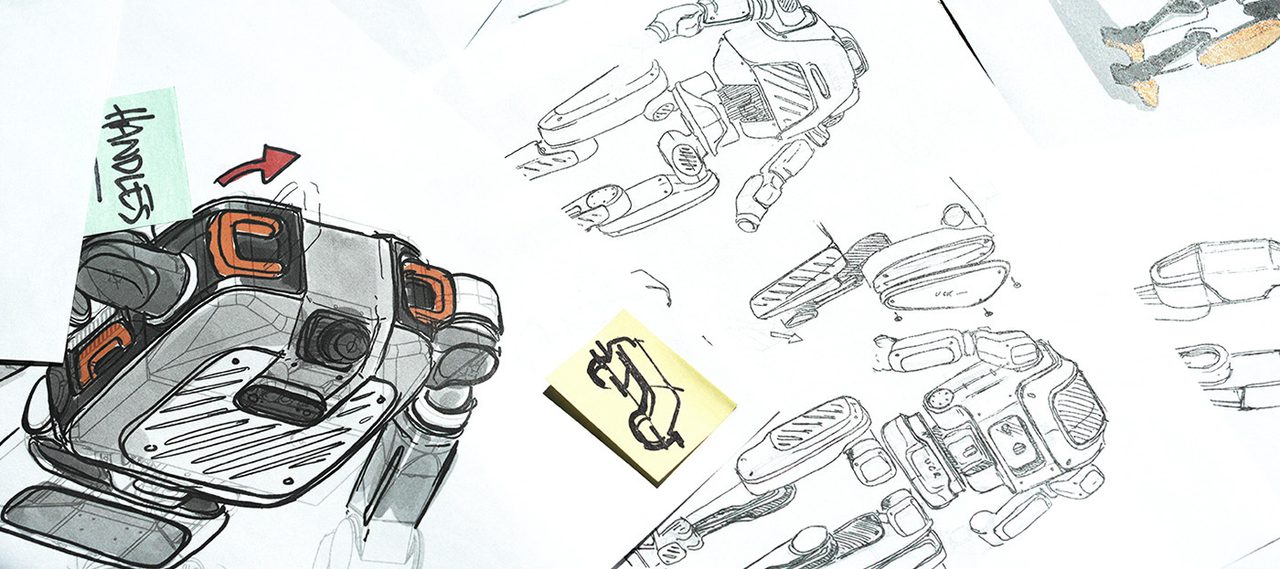

To push creative boundaries and accelerate iteration, we augmented our design workflow with generative AI tools. These techniques enabled broad ideation and helped surface novel configurations and forms—allowing us to challenge initial assumptions and explore a wider range of possibilities faster.

Solution

The final design for UCR expresses its function clearly through a tool-like visual language. Every element, from protective casing around sensors to treaded surfaces, visible handles, and areas of contrasting color, signals how the robot should be handled and what it’s meant to do. The design uses authentic materials and finishes to convey durability and intent, helping the robot feel like a practical jobsite tool.

Based on our experience designing for other autonomous technologies that require a high level of human trust, our team knew that the robot needed to be seen as something to direct and command: Not a hyper-intelligent presence, but a highly capable assistant. Its visual language is intentionally designed to understate its intelligence. This approach allowed us to reinforce human-machine trust and ensure that the robot fits seamlessly into team dynamics on active construction sites.

By positioning UCR as a supplier of rugged, task-oriented systems, Teague’s design helps open the door for broader adoption—enabling the robot to integrate smoothly with its human collaborators and be understood, trusted, and put to work in high-stakes environments.

Teague helped turn our vision into a design that is ready to work. Rugged, purposeful, and exactly what we needed.

Wei Ding

Co-founder & CEO | Under Control Robotics

Explore how we design autonomous systems at every scale—from individual platforms to integrated fleets.