Technology

Starlab full-scale high fidelity mockup

Category

Expertise

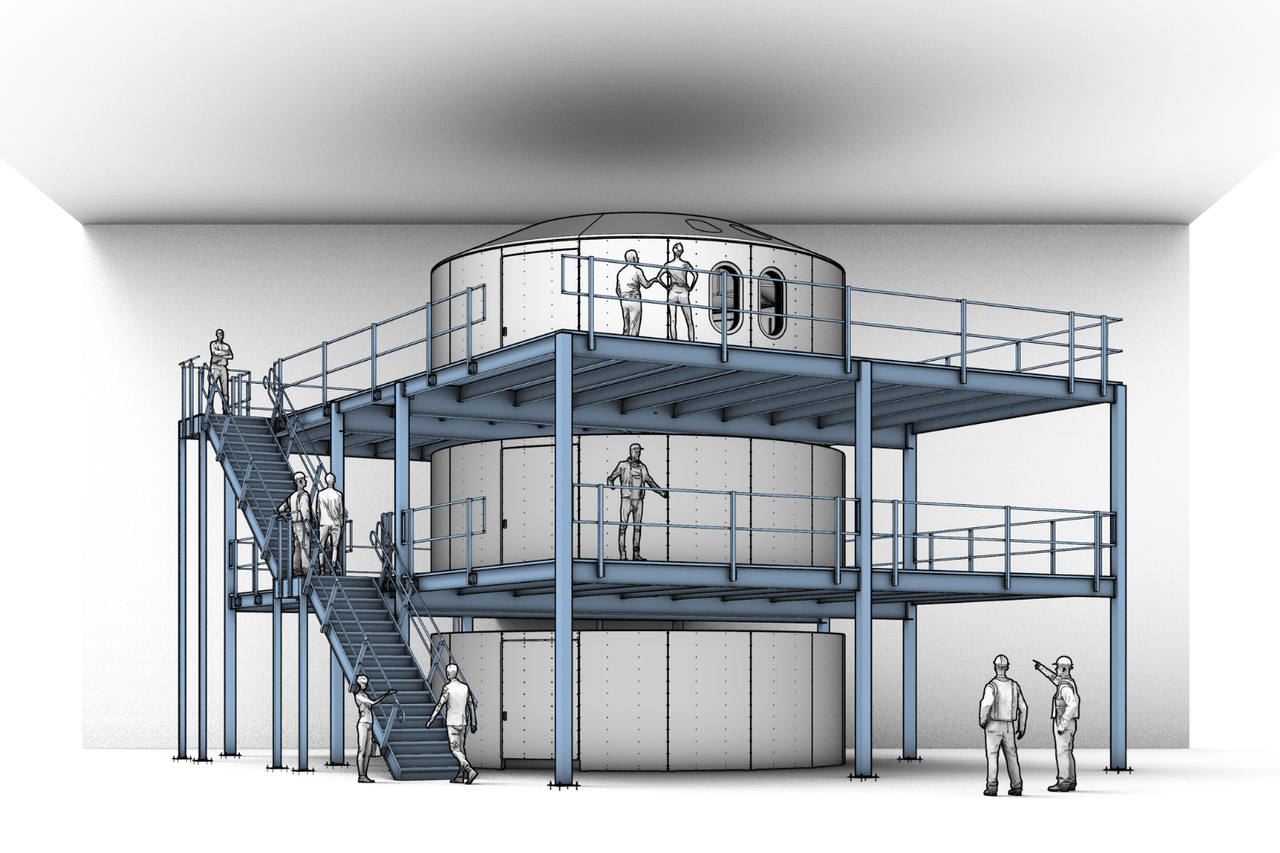

To help Starlab derisk its next-generation space station, Teague designed and built a full-scale, reconfigurable training and operations mockup at NASA’s Johnson Space Center.

Challenge

As the International Space Station nears retirement, Starlab—a joint venture led by Voyager Technologies—is racing to deliver its successor: a “science park in space” dedicated to microgravity research.

The habitat alone is enormous: a cylinder nearly 8 meters in diameter and 17 meters long, with roughly 400 cubic meters of habitable volume. When launched, Starlab is expected to be one of the largest single payloads ever put into orbit.

For NASA, astronauts, and commercial researchers, the stakes are high. Every person who flies to Starlab will need a place on Earth to learn the station, rehearse emergency procedures, and validate configuration and software updates before they’re pushed on orbit. Starlab needed a full-scale, high-fidelity mockup—a living twin that could support astronaut training and day-to-day operations for 20–30 years.

In order to meet Starlab’s rapid program schedule, work on the mockup happened concurrently with the station design. This strategic approach enabled early derisking and stakeholder engagement since engineering layouts, internal architecture, and even key structural elements were still evolving. Starlab didn’t just need a replica, they needed a robust, modular system that could adapt to ever-changing requirements and remain relevant for decades.

APPROACH

The mockup was to be installed at one of the few buildings capable of housing a structure like this, NASA’s Space Vehicle Mockup Facility (SVMF) at the Johnson Space Center, an “almost sacred” space where every shuttle and ISS astronaut has trained. Teague began with the basics: studying how to best fit the most critical elements of the massive station inside the SVMF, defining a scalable modular architecture for the mockup, and determining how to physically construct it on Earth.

Together with Starlab and NASA, Teague converged on a focused scope: a full-scale, three-level habitat mockup representing the heart of the station, with provisions to add the power and thermal element in the future. This configuration maximized training and operations value while fitting within site, safety, cost, and schedule constraints.

This collaborative, systems-level approach is exactly the kind of “complex problems solved beautifully” work that defines Teague-shaped projects.

To solve the structural puzzle, Teague drew on experience from an earlier low-fidelity human-in-the-loop (HITL) mockup and a VR-based habitat experience previously developed for Starlab. Rather than a self-supporting three-story cylinder, Teague proposed a standalone steel mezzanine: a three-level superstructure that carries loads and provides space for observers, desks, storage, and safe access circulation. The habitat “shell” mounts to this mezzanine, which is outfitted with its own power, data network, lighting, HVAC, and fire suppression—effectively a complete building inside another building.

Within each level of the habitat, Teague designed four independent structural systems—floor, exterior walls, shear walls, and ceiling—each engineered to be modular and replaceable. Individual panels can be removed to simulate access to valves or systems, or entire systems can be swapped out as the vehicle’s design evolves, without disturbing the rest of the mockup. This architectural strategy balanced stability and flexibility, creating a long-lived asset that can grow with the program while supporting immediate milestones with NASA.

Throughout, Teague’s team worked closely with Starlab and NASA—translating engineering requirements, operational needs, brand and public-storytelling goals, and safety codes into a single coherent solution. This collaborative, systems-level approach is exactly the kind of “complex problems solved beautifully” work that defines Teague-shaped projects.

RESULT

Functionally, the mockup serves as a long-term training and operations hub. Every astronaut flying to Starlab will rehearse nominal procedures, contingency operations, and emergency responses in this environment—just as generations of shuttle and ISS crews did in the same building. Every proposed engineering change, station configuration update, or mission-critical software release can be rehearsed and validated here before going live in space. In effect, Teague has created a durable, high-fidelity twin that allows the program to “try it on Earth first,” dramatically reducing risk when the cost of failure is highest.

Beyond training and engineering value, the mockup also serves as a public-facing showcase. Oriented to be highly visible from the Johnson Space Center’s visitor mezzanine, it anchors NASA’s first permanent commercial space station mockup on site—signaling a new era of collaboration between the agency and private partners. For Starlab, it becomes a powerful storytelling asset: a tangible, immersive representation of their science-first mission that every visitor, astronaut, and stakeholder can see and feel. By turning an evolving design into a flexible, future-proofed physical system, Teague gave Starlab and NASA a practical tool to manage complexity over the entire life of the program. The Starlab mockup doesn’t just mirror a space station—it accelerates its realization, derisks its evolution, and embodies Teague’s core promise: complex problems, solved beautifully.